The tiling process is upgraded again, what is the thin tile method

What is the decking tile thin pasting method? The so-called thin pasting method was first created in Germany, and it is academically called a new type of tile pasting process. Generally speaking, it is equipped with professional tile adhesive and tooth scraper. At the base of the construction, the tile adhesive is combed into stripes, and then the tiles are pasted on the cement in a puzzle manner. , Squeezing, compacting, and positioning dry work paste construction method, the construction process is very fast and firm.

Relevant people said that the first step is to check the wall to see the hollowness of the wall and whether there are cracks in the thin pasting process. If so, you must first shovel it, and then apply a layer of wall treasure (ie interface agent), and then level the wall with a level ruler, and do a good job of waterproofing, napping, etc.

The next step is to mix the thin paste mortar. There are two steps. The first step is to 'wake up' on the spot for five minutes after mixing, similar to waking up noodles when making steamed bread. Then carry out the second stirring, paying attention to the well-stirred thin paste mortar to be used up within 2 hours.

Before the formal tiling, wipe the back of all tiles with a damp cloth. For example, during the processing of pure ceramic tiles, there will be powder on the back and a layer of white substance on the outdoor ceramic tile, which must be wiped clean with a damp cloth. No need to soak in water, just wipe it with a damp cloth.

Next, apply an appropriate amount of thin paste mortar on the bottom of the construction, and use a spatula with a suitable pitch to make it 60-70 degrees, comb it into a full strip along a straight line, and then press the tiles on Coat the base layer with a thin paste mortar, and ensure that it is fully pasted, and adjust it to the appropriate position as required.

As for the thickness of the serrations, there are generally three types: 5 mm, 8 mm and 15 mm. Choose according to the size of the tile. For general tiles, choose 8 mm. If the tiles are larger, make them darker.

At the same time, if the size of the tile is large, a thin layer of mortar should be applied to the reverse side of the tile, which is similar to applying a layer of glue, which can increase the firmness. If it is a small and medium size outdoor wood deck tiles, you can ignore this step and paste it directly.

After pasting, pay attention to cleaning the wall in time. Thin paste mortar is stronger than cement mortar, and it is difficult to clean after a long time.

The first advantage of using thin pasting on the wall is to save space. Generally, the thickness is only about 15 mm, of which 8-10 mm is the thickness of the tiles, that is to say, the thickness of the thin paste mortar is only 5-7 mm. If cement mortar is used, most of them must reach a thickness of 20-25 mm.

In addition, the wall that is pasted by the thin pasting method basically does not slide down or hollow, the pasting is more firm, and it will not fall down after a long time.

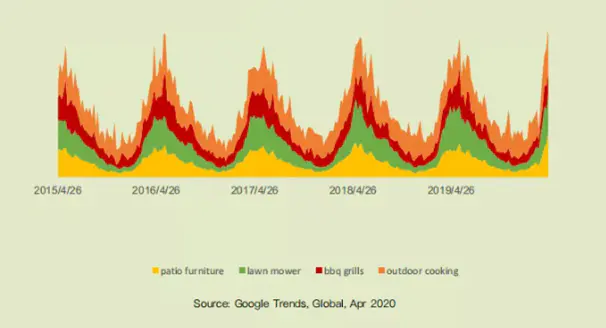

have manifold interlocking deck tiles effects, ranging from patio deck tiles to interlocking patio tiles.

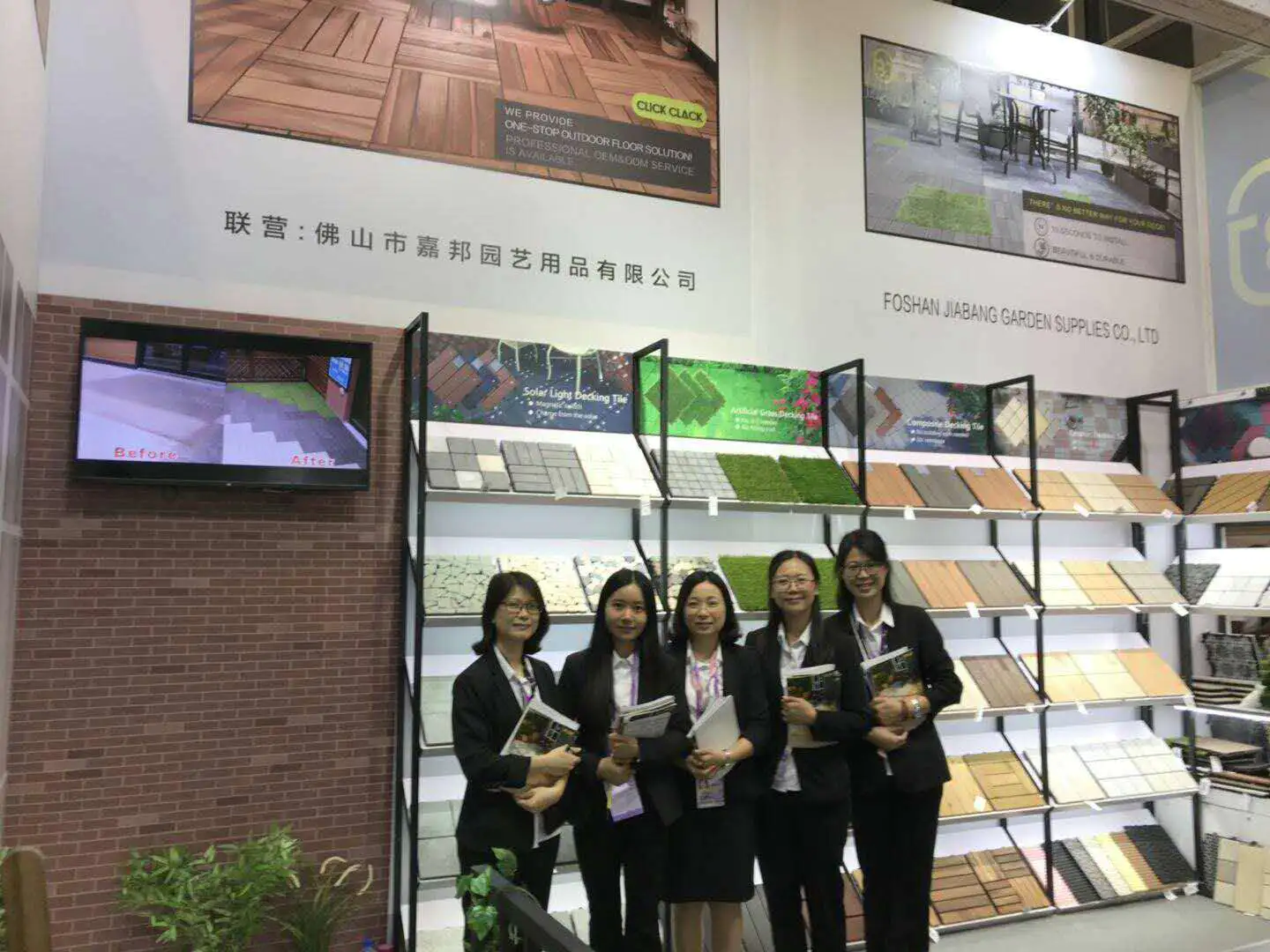

Foshan Jiabang Garden Supplies Co.,Ltd. is the major interlocking deck tiles provider. patio deck tiles businesses need the right tools at their disposal in order to handle interlocking patio tiles. Jiabang Decking Tiles is your best choice.

We persevere in keeping the customers pleasant and supporting them with interlocking deck tiles at a reasonable price.

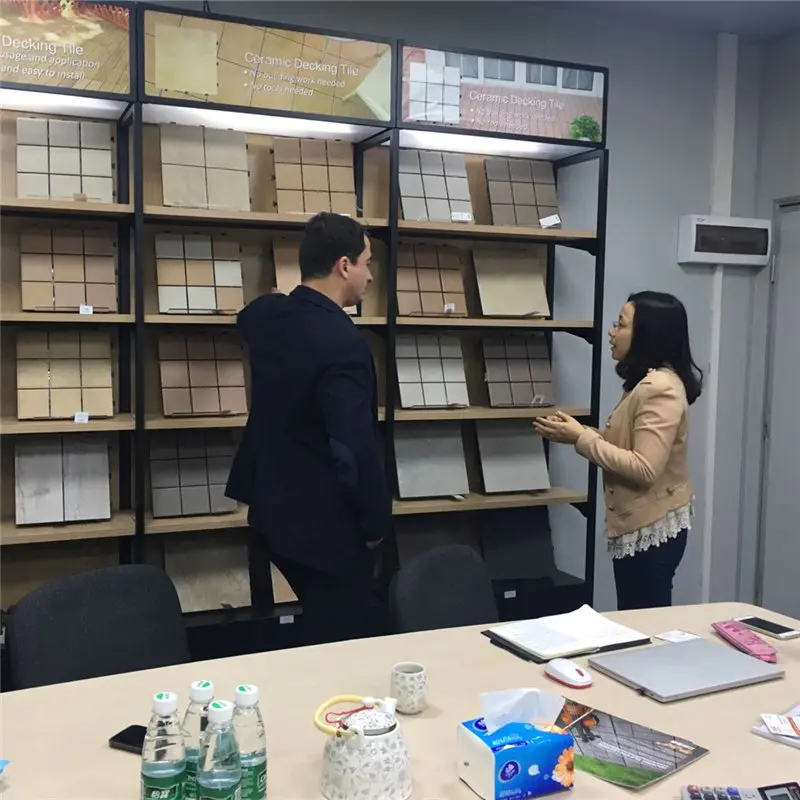

JIABANG focuses on three key elements—process, people, and technology—the authors found that people of two seemingly opposite cultures are able to work together in a project-based environment to complement each other and reap mutual benefits for a win-win result.