How much is a piece of ceramic tile?

to buy ceramic tile, in addition to indulge in this kind of nice design and color, many people are confused in the price of ceramic tile, watching the same ceramic tile, is many times more expensive than low prices high, the so-called fire cabbage price package price would really buy cheap and fine ceramic tile, shihezi decoration small make up remind buy than selling fine, good brick will never sell cheap, below introduce you to affect the price of ceramic tile height difference between the nine factors, watching you will understand!

ceramic tile price of 9 factors differ big:

1. Production line is not the same factors

good ceramic tile factory has more advanced, full automation, modern production line, the general factory is semi-automatic production line by the manual workers. The quality of ceramic tile is to rely on lean production and control, only the most advanced production lines, can produce the best quality products, good equipment production line is the guarantee of good products.

2。 Is not the same as the test factors

after every piece of brick machine factory inspection, artificial barrier. Strict inspection size, specification, color difference. National standard is the same, but each factory internal control standard is different, good factory strict internal control standards, ordinary factory internal control standard is relatively loose.

3。 Press different factor

the size of the compressor can't decided to make good brick is poor, but with a large tonnage press can make small tonnage press can't make the product. Such as small tonnage press can't make like x1600mm 800 specifications of the big outdoor wood deck tiles. Press tonnage from 200 - in the market now 7200 tons, the press tonnage directly determines the density and hardness of ceramic tile.

4。 Iron factors is not the same as

good ceramic tile factory using high magnetic electric magnet adsorption iron filings, iron content below 0. 1%, ensure the body after firing without impurities, black brick pure. Ordinary manufacturer USES ordinary magnet in addition to iron, iron content is higher, fired from easy to appear black spots on the surface of the ceramic tile.

5。 Raw material is not the same factors

the same equipment in the same process, why make products are different? The answer is, using different raw materials, good material to make a good product. impurity content in the raw materials will greatly affect the quality of ceramic tile, the current domestic best porcelain originated in southern hilly areas.

6。 Stale factors is not the same as

after ceramic tile by ball mill and sieving in addition to iron, over a period of time of stale, to make all kinds of impurities in raw material and chemical reaction in full, in order to achieve production standards. Have the strength of outdoor ceramic tile manufacturers, each stale can reach more than one thousand tons of raw materials, and can reserve more than 180 days of inventory. And the stale of raw materials needed to enterprise larger material and financial resources, the general enterprises to save costs, improve the yield rate, will shorten the time of stale.

7。 Fire time is not the same as

the firing of ceramic tile of the length of time a great influence on the quality of ceramic tile, time is short, the ceramic tile can't burn, we often see brick embryo with a 'dirty', is the reason why not to burn through. For example: 320 meters long kiln, same good factory production could only a third of the general factory, is because of good factory fire special time. Bo changes a brick of 800 * 800 mm need to burn 70 minutes, only 40 - general factory 50 minutes. Fire the extension of time, ensure full porcelain brick, like bowls is close-grained, high hardness, wear resistance.

8。 Different drying kiln factor

the length of the drying kiln, determine the moisture dry degree of outdoor ceramic tile. Such as: good factory adopts horizontal roller kiln, the dry speed, not only can satisfy the green that adobe water from inside to outside, make the moisture content lower than 0. 5%, and fire will not be out of shape. Most importantly, personalized Settings, can greatly improve the workshop of the workers' working conditions.

9。 Ball mill is different factor

the stand or fall of ball mill, and the speed of ball mill and ball mill time, directly influenced the density of ceramic tile to suppress, wear-resisting degree and anti-fouling ability. Good ceramic tile manufacturers using large-tonnage ball mill, through the wear-resisting aluminium oxide ball stone long ball mill processing, ensure the raw materials of coarse particle becomes finer, more uniform, or even a third of the fineness is only a human hair. And ordinary ceramic tile factory, is the small tonnage of ball mill is used and the low aluminium ball eggs, to save the production cost, shorten the time of ball mill, sold on the market price is low, but there is great use hidden dangers.

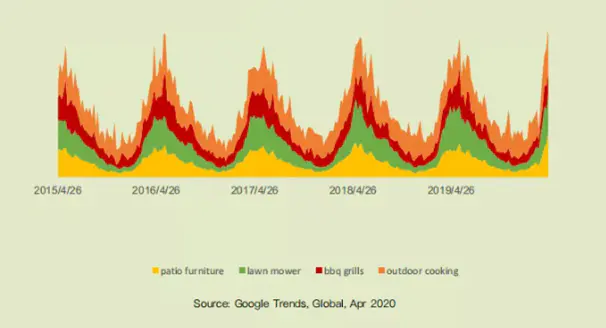

There is a strong need for more research on , in order to be able to provide strong and conclusive evidence of their patio deck tiles effects. However, recent studies have provided valuable insights into how the intake of may result in improved interlocking patio tiles.

Review Foshan Jiabang Garden Supplies Co.,Ltd.'s progress at regular intervals, so we can continue with the strategies that work well and change or eliminate the ones that don't give the results we are looking for.

Foshan Jiabang Garden Supplies Co.,Ltd. can promise you that we never conceded on the quality standards of our products.