How to make ceramic tile?

ceramic tile is the time to decorate an essential material fee, but do you know the appearance is so high light of the production process of decking tile is more complicated? This small make up from some official website refer to the some technology of ceramic tile production, hope you see see! ( production)

1。 ceramic tile material

the material is quite high demand, inspection is very strict, mainly including sampling, try playing cake burning, physical performance test, chemical analysis, etc. Raw material inspector first sampling for new warehouse of raw materials, and water samples; Then inspector will sample according to the procedures flour, bread, and tried to burn, and try to burn after sample of whiteness, test the physical properties such as strength, bibulous rate, at the same time, the lab technician from pulverizing link part extract powder for chemical analysis, testing all kinds of chemical composition content in the raw material is in line with the technology requirement of the factory, in to the factory.

2。 Powder with

after grinding powder, tested in accordance with process quality requirements in the slurry pool, on the way to the sieve in addition to iron. Sieving is to remove the ball mill without grinding fine coarse particle and some impurities; Because in addition to iron iron affect the whiteness of ceramic tile, but also in the formation of black spots on the surface of the ceramic tile, melt hole, impurities, so must go through multi-channel strict in addition to iron.

3。 Pressed into bricks

the preparation of fine powder will be sent to press process, through the mould material, to exert some pressure on the powder, the powder was pressed into bricks. It is important to note that in the process of pressed into bricks, must ensure the quality of powder and the proper operation of the press process, otherwise it will directly affect the quality of the tile.

4。 printing

after forming, the strength of adobe is very poor, due to the moisture content of the bricks, goes through dry is the free water evaporates in the bricks, on the one hand can increase body strength, reduce the body is damaged, can avoid waste into printing and firing process, unnecessary loss; On the other hand also can avoid the tile kiln firing of the moisture content is higher, the body cracking caused by moisture intense evaporation.

5。 Polishing

the last step is to ceramic tile is the sublimation of the whole, after firing the ceramic tile of semi-finished products should pass edge grinding polishing after leveling edge grinding air drying and other steps, to become what we see in the exhibition hall pieces of exquisite light smooth ceramic tile.

simple for the production of decking tile is these operation, little step can make ceramic tile is not complete, want to know more related content welcome to continue to pay attention to our website! Here are the most authoritative information, finally thank you for watching! The next issue we goodbye! ( production)

At the same time, as the recent research of JIABANG shows, the benefits of improved productivity and firm performance can make implementing basic management practices worth it.

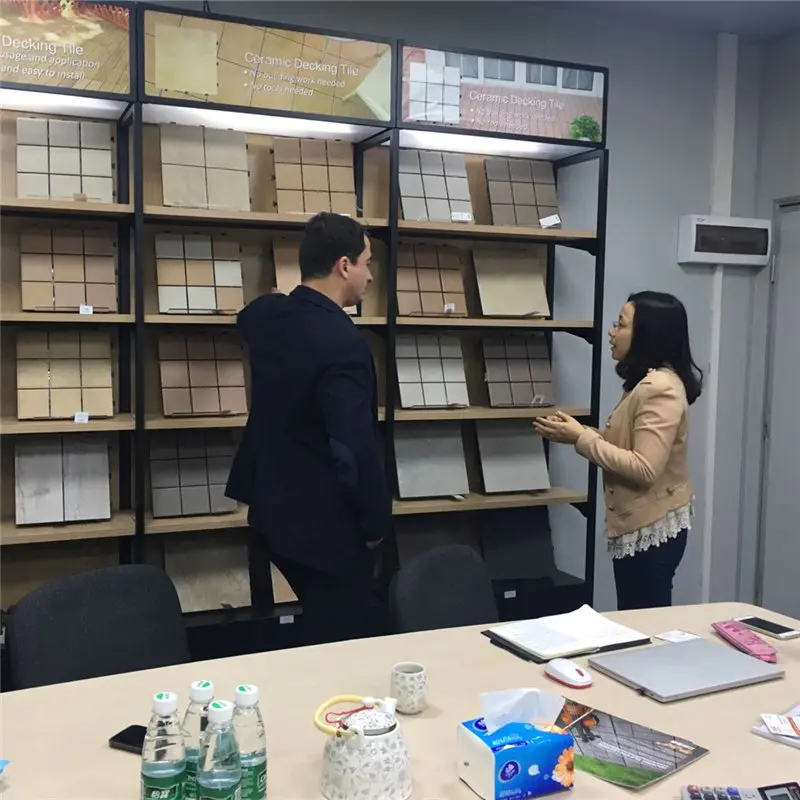

At Foshan Jiabang Garden Supplies Co.,Ltd., we make sure everything we do honors that connection – from our commitment to the highest quality in the world, to the way we serve our customers and communities to do business responsibly. We are looking forward to becoming trusted supplier of every customer, inquire us at Jiabang Deck Tiles!

Using high-quality materials to produce interlocking deck tiles is one of the most important part during manufacturing.

interlocking deck tiles are less complex compared with interlocking patio tiles.