Ceramic tile is as white as possible?

by:JIABANG

2020-10-04

When consumer is buying ceramic tile, often think decking tile the blank of the white the better, they think that the pure white, no impurities, brick is good.

This really the case?

Let's look at let the body for a higher degree of white ceramic tile ways: (1) use a higher degree of white ceramic tile body raw materials made of clay, quartz and feldspar calcine, raw materials generally white color, but the raw materials each place to show some differences, whiteness is different also.

Guangdong, for example, white clay, and branching channel of the yellow soil, the same technology and process, of guangdong outdoor wood deck tiles firing white body, and branching channel is partial red, even through all sorts of removing impurity, the decking tile of branching channel of the body is not so white in guangdong ceramic tile.

Other regions, too, because of the soil, the glaze ceramic tile no guangdong white body.

(2) strengthen the removing impurity process before firing ceramic tile, raw material for removing impurity, some color golden, such as iron ion is filtered out.

In the process, the more careful, the body will be more white.

(3) in the mud is expected to add zirconium silicate reach whitening effect of ceramic tile manufacturers use in the method of adding zirconium silicate clay material more to increase the whiteness of body.

Zirconium silicate is a kind of high-quality opacifying agent, is widely used in various construction ceramics, sanitary ceramics, ceramics for daily use and production of ceramic arts and crafts, etc.

Its whitening effect is mainly due to firing after the formation of the baddeleyite can form of incident light scattering, the scattering generates opacifying whitening effect.

Zirconium silicate in the application of brick of pottery and porcelain, one kind is to use in glaze, another kind is used in the body.

Glazing thickness of brick of pottery and porcelain is generally not more than 5 mm, glaze in a piece of brick of pottery and porcelain quality percentage is less than 5%, and the amount of zirconium silicate in the glaze, generally no more than 20%, otherwise it will affect the surface decorative effect, so for the whole piece of brick of pottery and porcelain, the glaze with the quality of zirconium silicate is not more than 1%.

In the application of the ceramic tile body, zirconium silicate content is generally not more than 2 -

3%.

So, ceramic tile is really the white the better?

From the perspective of the raw material, because use adobe white the white clay such high whiteness of raw materials.

But at present, our country low white clay resources, with the development of ceramic industry vigorously, white clay resources dries up, a white materials often represents the higher cost of production.

So in recent years on the market tiles blank whiteness than before has declined.

Some manufacturer for equipment, technology and other reasons, in the process of removal of impurity of raw material is not complete, leading to ceramic tile body presents a grey, black, yellow wait for color, this kind of brick do not removing impurity completely white body good.

But this does not mean that the white ceramic tile is the pure, the better.

Some enterprises in the production of add zirconium silicate, talcum powder, such as 'whitening agent', also can make the ceramic tile body become more white.

But if the dosage exceed limit may cause harm to human body.

It is worth noting that the zirconium silicate in itself is not radioactive, but due to the raw material of zirconium silicate mineral zircon sand, so inevitably mixed with a small amount of radioactive material, such as Ra (

Radium)

、U(

Uranium)

、Th(

Thorium)

、K(

Potassium)

And so on, so few dosage of zirconium silicate in the brick of pottery and porcelain and has strict rules.

But illegal manufacturers in order to pursue individual beautification body may add excessive zirconium silicate in the ceramic tile.

So consumers in the process of buying ceramic tile, ceramic tile to pay more attention to the 3 c certification and belongs to the types of radioactive does not conform to or does not indicate the type is not qualified.

(

A kind of material to use is not restricted;

Class B material is not available in the civil building interiors, available only in the civil building of veneer and other buildings facing inside and outside;

Class C material is used in civil construction, only as other building exteriors side)

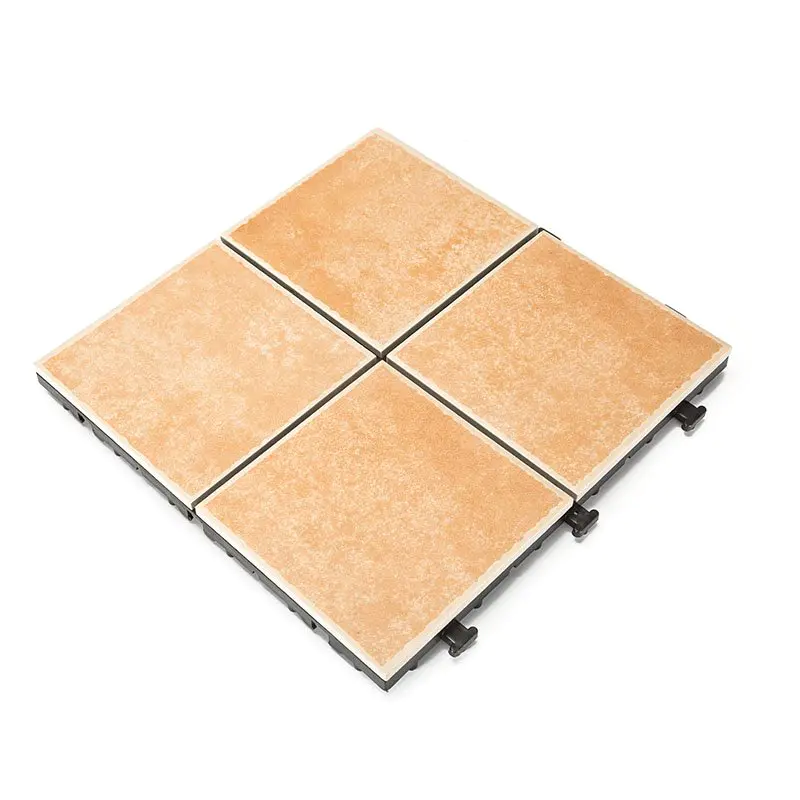

JIABANG is the leading manufacturer of interlocking deck tiles and related products.

To know more about interlocking deck tiles interlocking patio tiles, visit Jiabang Deck Tiles for more reviews, tips and advice. Foshan Jiabang Garden Supplies Co.,Ltd. won't let you down for your options. visit!

Foshan Jiabang Garden Supplies Co.,Ltd. needs to ensure we're resolving customer issues as quickly as possible. By doing so, it leads to positive customer experiences and brand loyalty.

interlocking deck tiles is one of the best products sold in the market today.

JIABANG is the leading manufacturer of interlocking deck tiles and related products.

To know more about interlocking deck tiles interlocking patio tiles, visit Jiabang Deck Tiles for more reviews, tips and advice. Foshan Jiabang Garden Supplies Co.,Ltd. won't let you down for your options. visit!

Foshan Jiabang Garden Supplies Co.,Ltd. needs to ensure we're resolving customer issues as quickly as possible. By doing so, it leads to positive customer experiences and brand loyalty.

interlocking deck tiles is one of the best products sold in the market today.

Custom message