Company Advantages1. The design of JIABANG plastic

interlocking deck tiles is elaborately designed with the combination of functionality and aesthetics.

2. The product will never be out of shape. Its heavy-duty components and parts are perfectly designed to withstand extreme industrial conditions.

3. This garment would be a source of satisfaction and looks nice. It has the optimum amount of ease and its seam lines follow the general silhouette of the body.

/ Product information

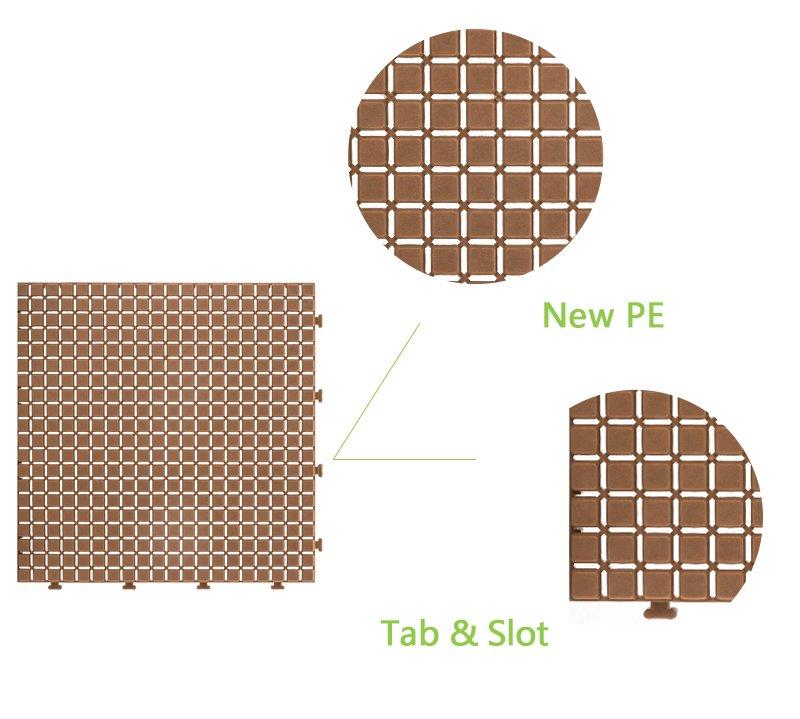

Plastic mat is an innovative product compare with the traditional tile, made by new PE material which is more flexiable and durable. It is an ideal choice for bathroom, kitchen, garden flooring. The plastic mat has pebble/mosaic design with non slip surface, available for different color. no maintanence, quick installation, no tools, no adhesive needed.

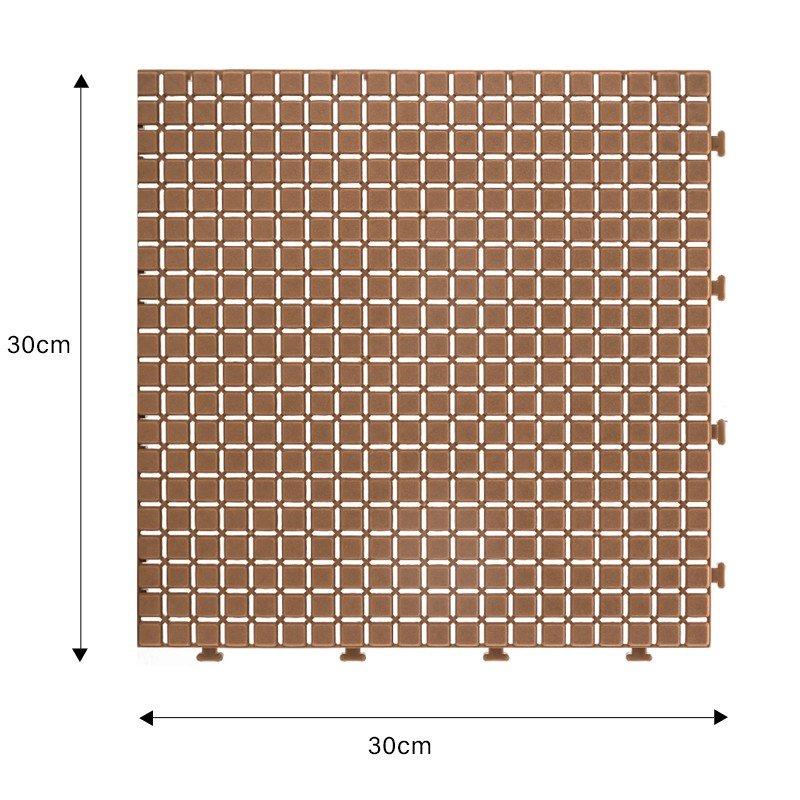

Specification

Product name

Color

Sand

Material

PE

Size

30*30cm

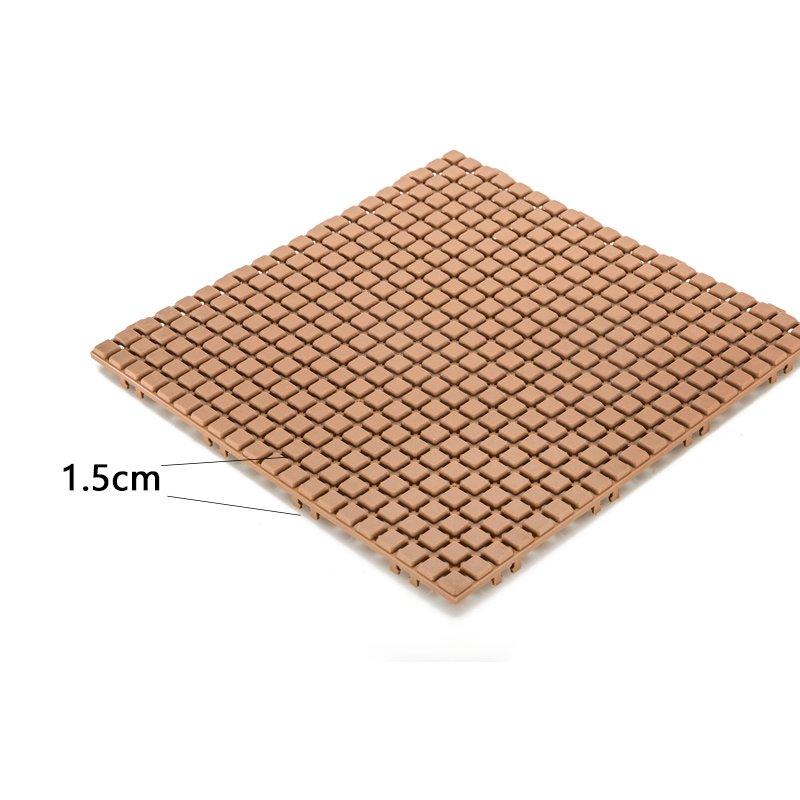

Thickness

1.5cm

N.W

0.3 KG

1 square meter

around 11 pcs

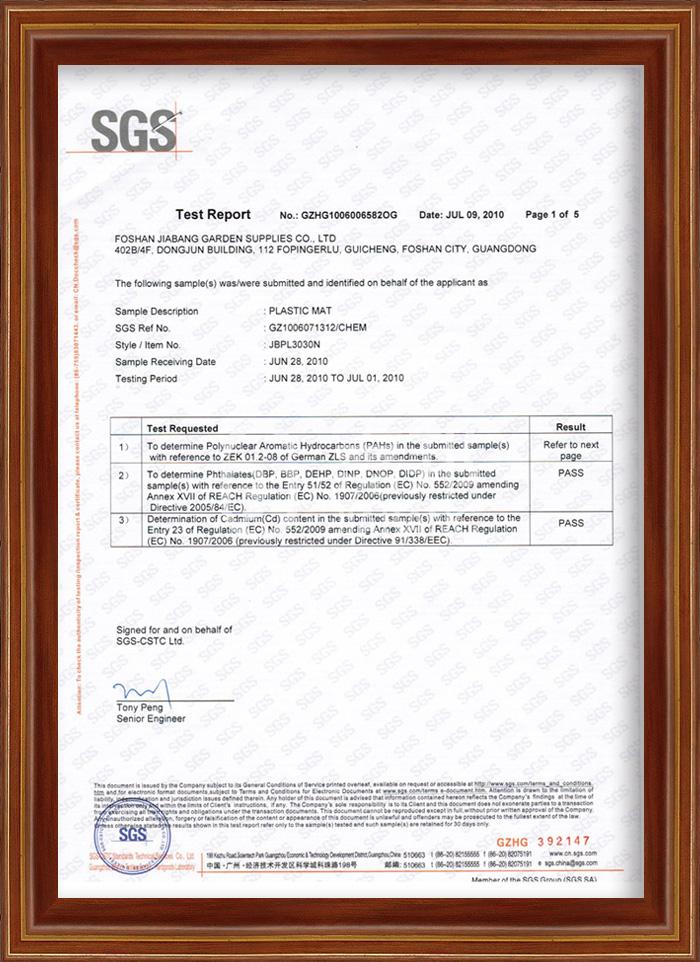

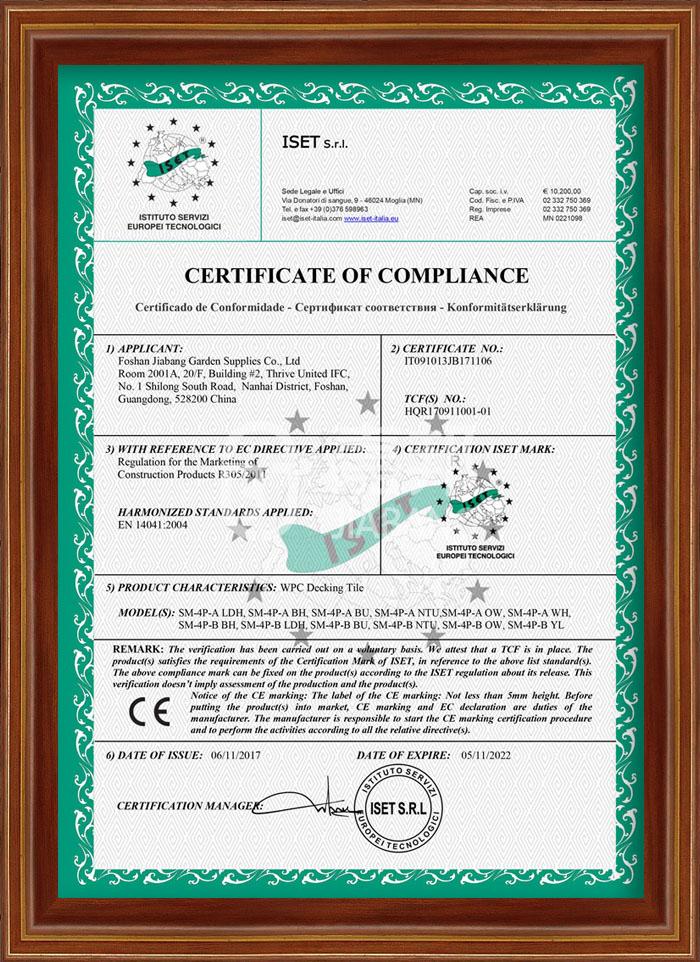

Certificate

CE, ROHS, REACH

Application

Indoor like bathroom, Kitchen. Outdoor like garden, patio,balcony,terrace, sunroom,etc.

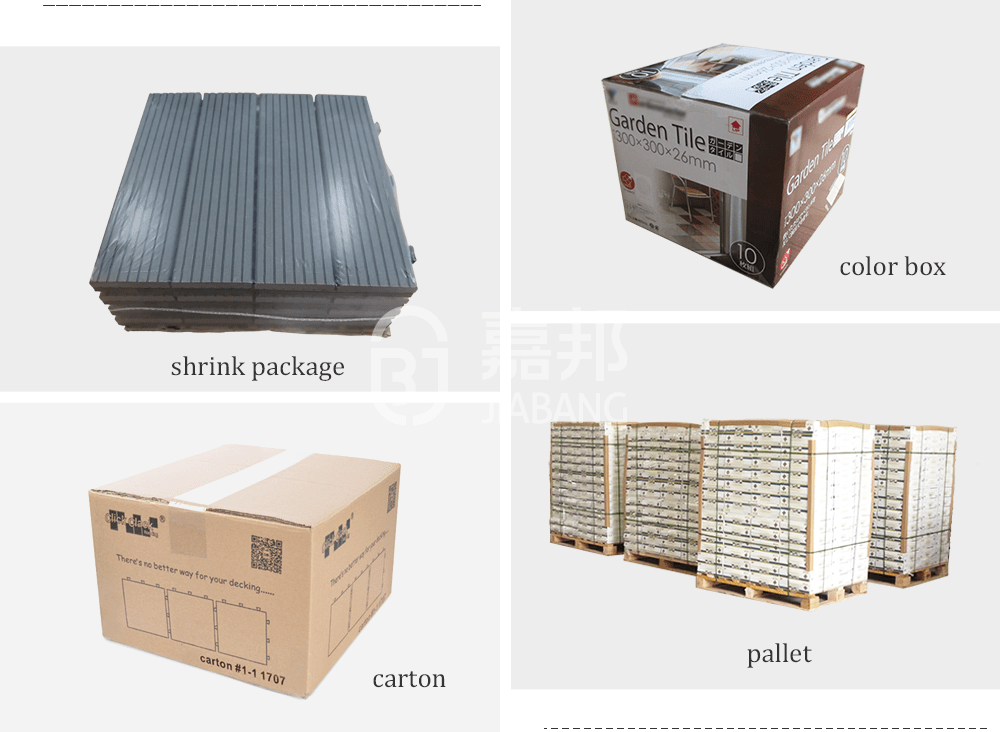

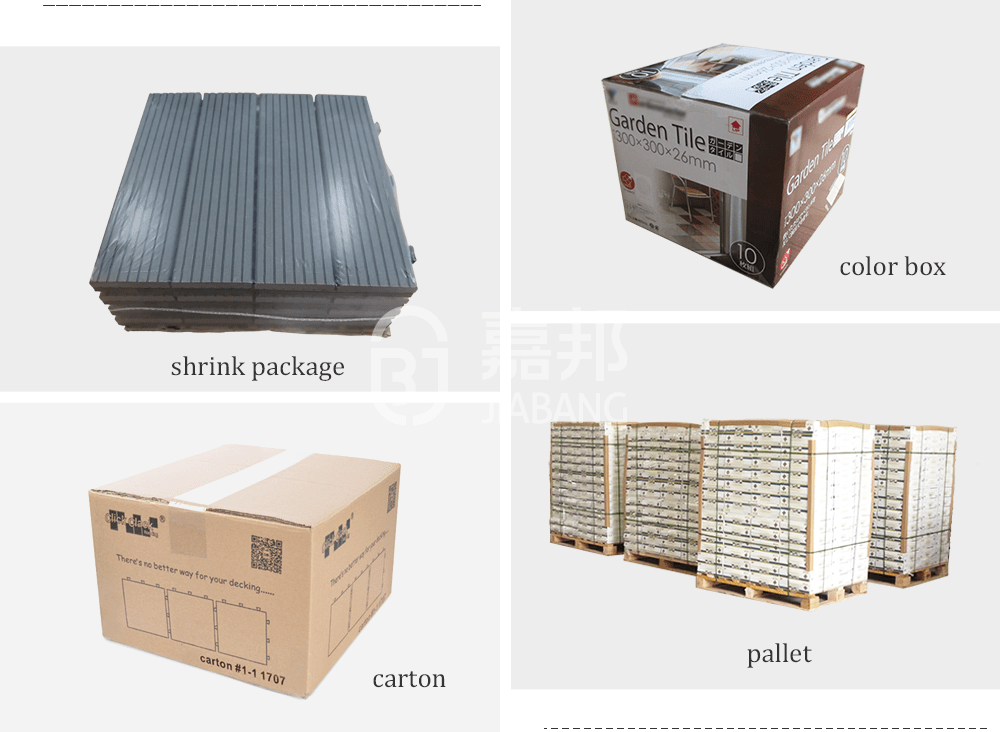

Optional package

brown carton, color box, shrinkage film, window box, display box, pallets,etc.

/ Product details

Top material

100% new PE with molded shape.

/ Project display

For kitchen

.

Plastic mat JBPL3030N sand for kitchen.

For bathroom

.

Plastic mat JBPL3030N sand for bathroom

For balcony

.

Plastic mat JBPL3030N sand for balcony.

/ Installation

No Special Tools Required

You don't need any adhesives, tiles spacers or grout or to lay Decking Tiles. Everything you need for a quick and easy installation is included in each box.

Step 01

Prepare the Surface

Interlocking Tiles can be placed on most hard surfaces. However, it's important that the surface is as smooth as possible, with no bumps, large cracks, uneven areas or surface depressions that would allow the

Decking Tiles to "rock" in place. If the surface is particularly uneven, you may need to level the surface with some patching compound or filler. We do not recommend the installation of Inter Locking Tile on bare ground.

Step 02

Plan Your Design

It's easy to create unique patterns, designs and borders by using a combination of different tile styles. You can sketch your design on paper to try various design combinations. The possibilities are endless!

Step 03

Lock the Tiles into Position

Start by placing an Interlocking Tile in the corner of the area that you want to cover, making sure the two sides of the tile with the tabs showing are facing outwards in the direction you will be laying the tiles. Place the edge of the next tile without the tabs showing over the black connecting tabs so these tabs lock into position with the corresponding slots on the underside of the second tile. Repeat this simple "lock in place" process with the remaining tiles, working in a diagonal direction across your entire design.

Step 04

Completing Your Project

You can generally avoid cutting Interlocking Tiles where you need to fit around fixed objects, odd shaped areas or against walls simply by filling in the gaps or spaces with medium sized pebbles, volcanic rock or other landscaping material.

/ KEY FEATURE

Easy

install

Easy

install

Quick and easy install, no skills

needed.

No

Maintenance

No

Maintenance

No Maintenance needed.

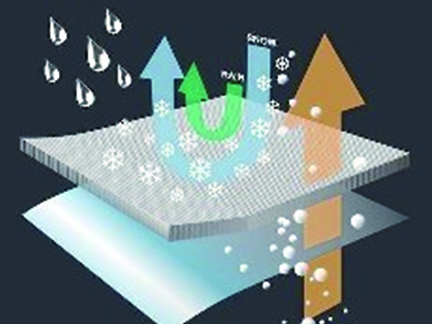

Water

drainage

Water

drainage

Non slip surface, perfect water

drainage system.

DIY

concept

DIY

concept

Available in wide range of

materials.

/ PACKAGE

We offer wide range packing method to fullfill

various customers different requirement.

carton, color box, shrinkage film, pallet,

display box, or other tailor made package.

/ CERTIFICATE

Company Features1. Foshan Jiabang Garden Supplies Co.,Ltd. is a best manufacturer and trader of plastic interlocking deck tiles with a long history of delivering top value for customers.

2. Foshan Jiabang Garden Supplies Co.,Ltd. has a professional plastic floor tiles production base.

3. To provide the best plastic garden tiles and serve well is the mission for JIABANG to accomplish. Inquire online! Foshan Jiabang Garden Supplies Co.,Ltd. endeavors to become one of the leading outdoor plastic tiles manufacturer. Inquire online! Foshan Jiabang Garden Supplies Co.,Ltd. aims to be the first to break into emerging markets. Inquire online!

Easy

install

Easy

install

No

Maintenance

No

Maintenance

Water

drainage

Water

drainage

DIY

concept

DIY

concept