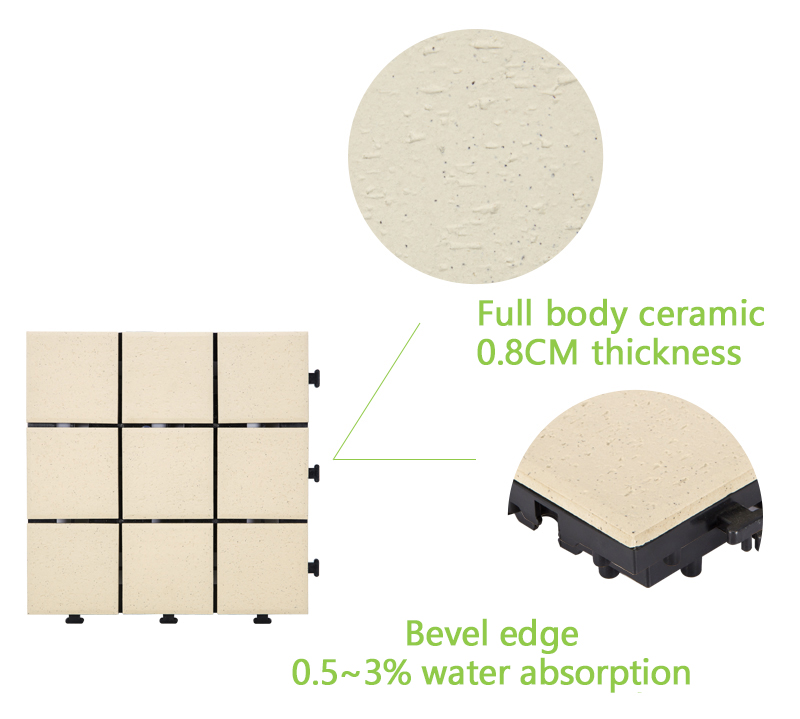

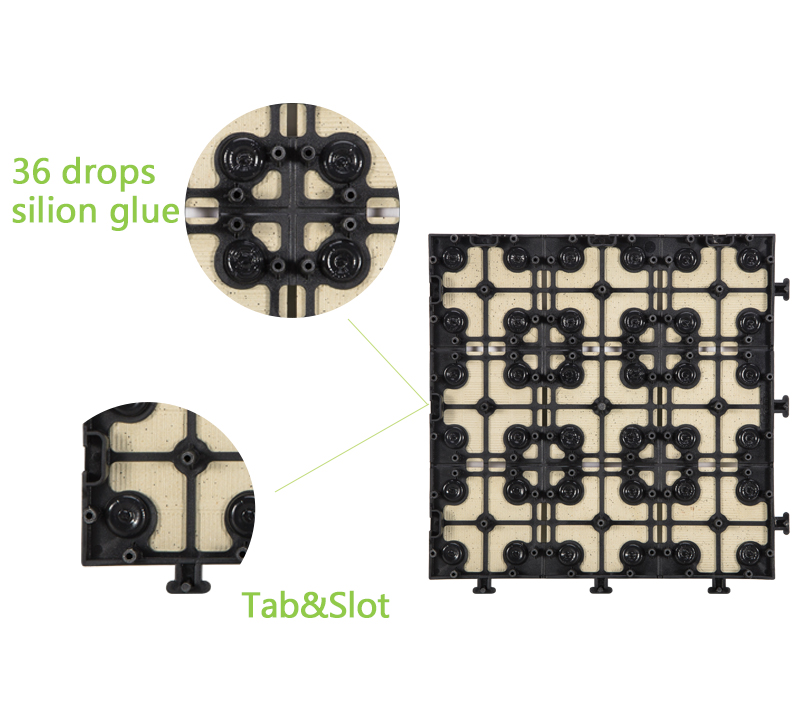

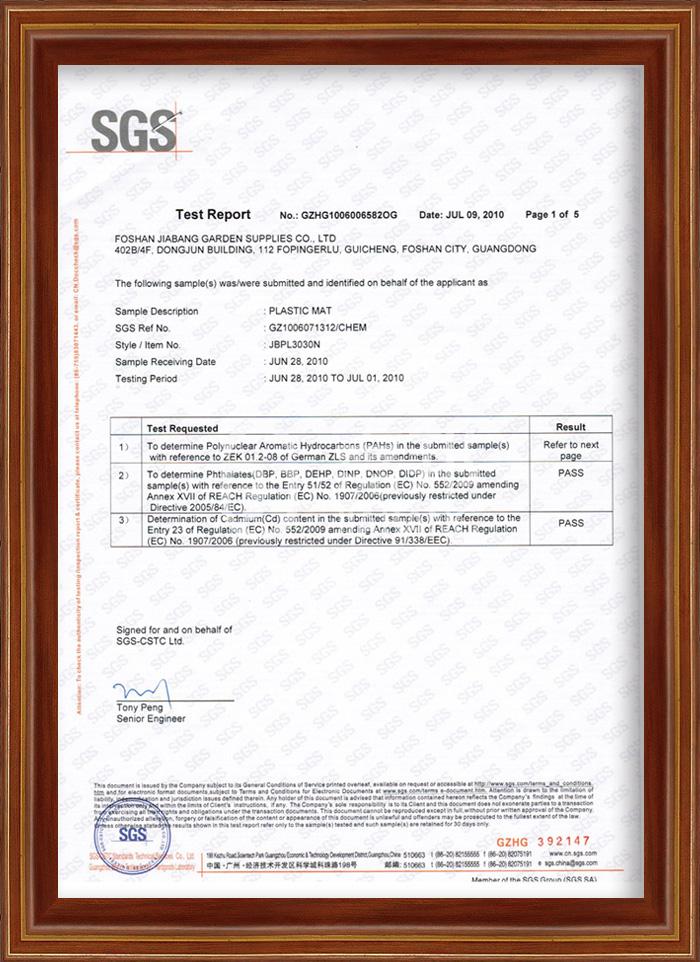

0.8cm ceramic interlocking tile is an outdoor floor decking tile, combined ceramic tile and new PE plastic base by 36 drops of silicon glue, not easy seperated, anti slip surface, quick installation, no tools, no cement needed, widely used in patio,garden,paver deck,etc.

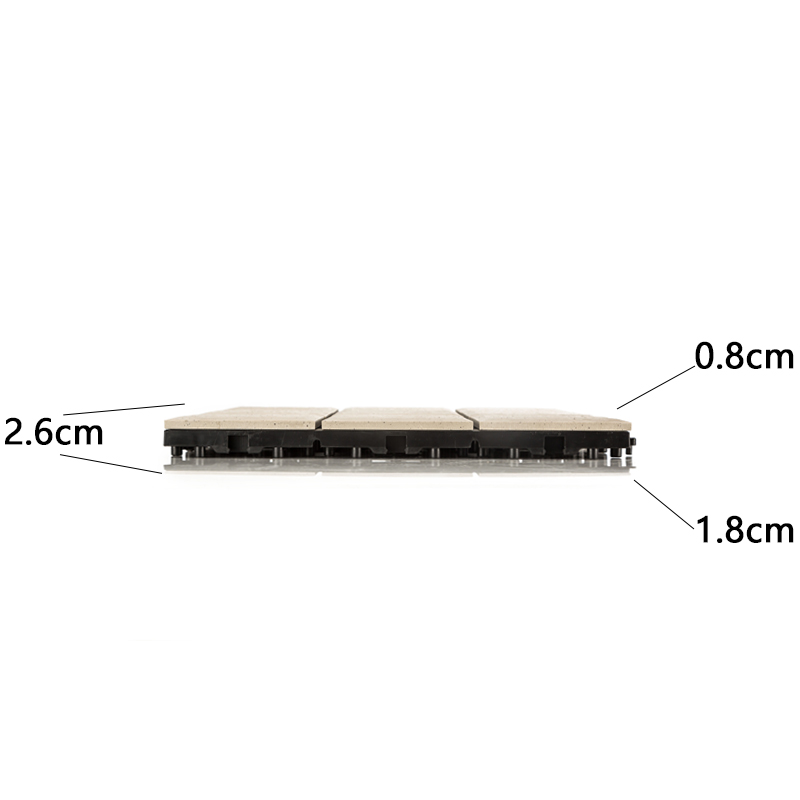

Specification

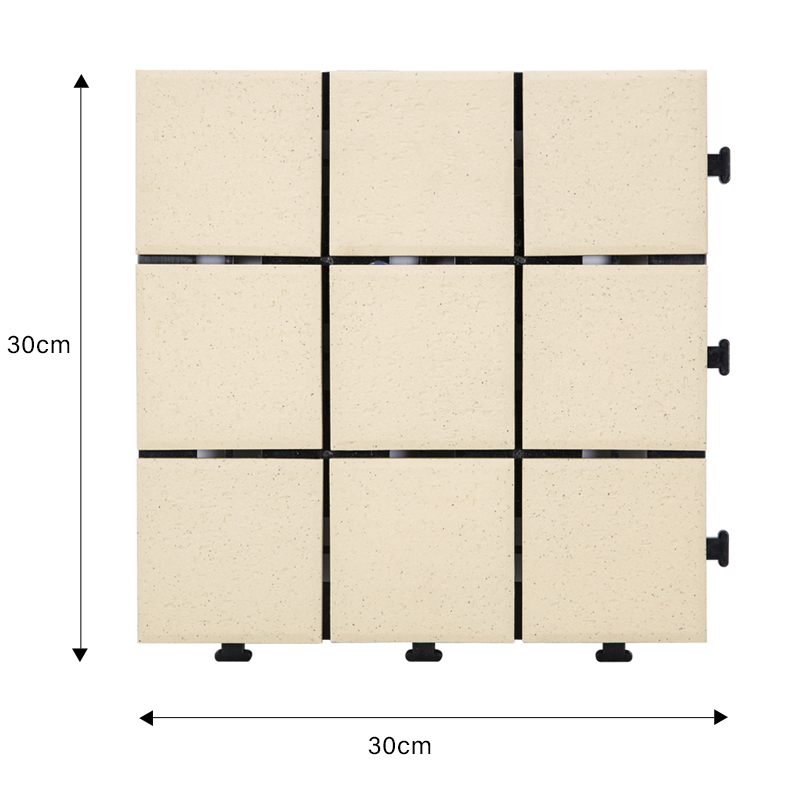

Front view

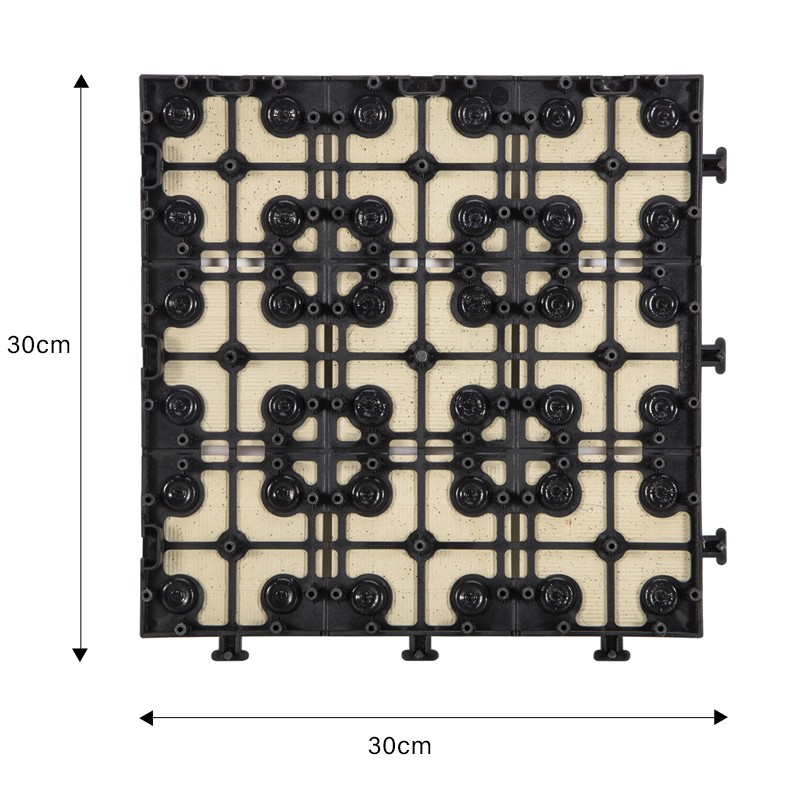

Back view

No Special Tools Required

You don't need any adhesives, tiles spacers or grout or to lay Decking Tiles. Everything you need for a quick and easy installation is included in each box.

Easy install

Easy installQuick and easy install, no skills needed.

No Maintenance

No MaintenanceNo Maintenance needed.

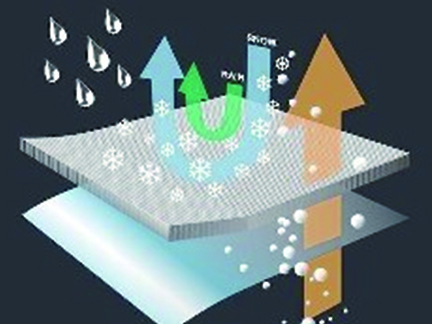

Water drainage

Water drainageNon slip surface, perfect water drainage system.

DIY concept

DIY conceptAvailable in wide range of materials.

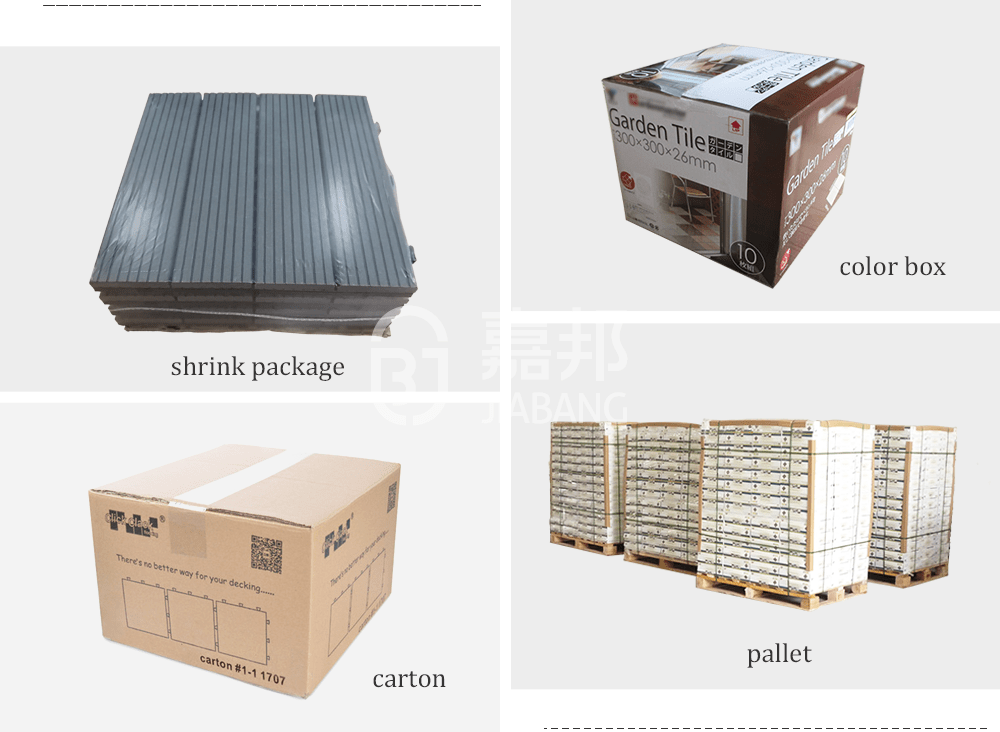

We offer wide range packing method to fullfill various customers different requirement.

carton, color box, shrinkage film, pallet, display box, or other tailor made package.

Copyright © 2025 Foshan Jiabang Garden Supplies Co., Ltd | All Rights Reserved Design by www.diytile.net 粤ICP备12006862号.

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist